The Reason Why DTF Printing is the Future of Custom-made Clothing Manufacturing

The Reason Why DTF Printing is the Future of Custom-made Clothing Manufacturing

Blog Article

Technologies in DTF Printing: How It's Revolutionizing the Market

The fabric printing industry is going through a substantial change, driven by the innovative advancements in Direct-to-Film (DTF) innovation. These developments are not just boosting print quality and flexibility however likewise simplifying the whole printing procedure. With superior ink formulations, enhanced film and sticky technologies, and the combination of automation, DTF printing supplies vibrant, resilient prints on a selection of textiles, fulfilling the enhancing demand for personalization. As services look for extra efficient and eco-friendly solutions, the effects of these developments require a closer assessment right into how they are shaping the future of textile printing.

Developments in DTF Technology

Advancing rapidly, DTF (Direct-to-Film) printing innovation has undergone substantial enhancements that are revolutionizing the textile industry. Modern DTF printers make use of advanced ink formulas that result in vibrant, long lasting prints with high resolution and color accuracy.

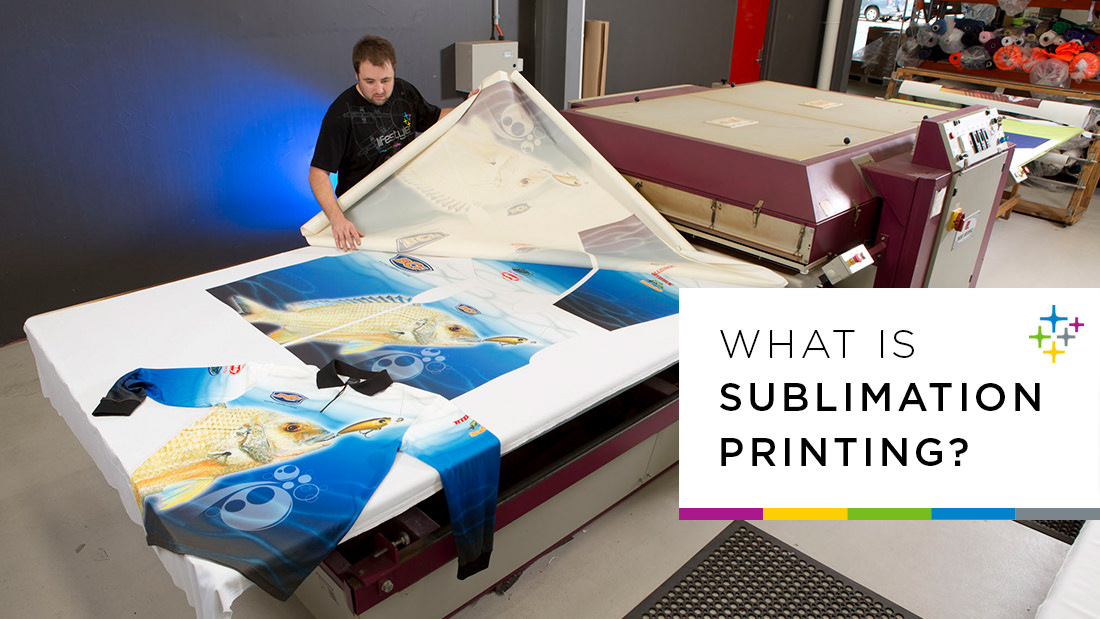

In addition, developments in film and sticky modern technologies have improved the general application procedure. New films provide better elasticity and bond, improving the toughness and washability of the published layouts - sublimation printing. This guarantees that the prints preserve their integrity and vibrancy even after multiple cleans

Last but not least, ecological factors to consider have prompted the development of eco-friendly DTF solutions. Suppliers are significantly taking on sustainable practices, such as using recyclable movies and water-based inks, straightening with worldwide efforts to reduce the sector's eco-friendly footprint.

Benefits Over Traditional Approaches

When contrasting DTF printing to traditional approaches such as display printing and direct-to-garment (DTG) printing, a number of distinct benefits emerge. sublimation printing. One of one of the most considerable advantages is its convenience in material compatibility. Unlike display printing, which commonly requires details material types, DTF printing can be related to a more comprehensive variety of materials, including cotton, polyester, and blends, without compromising print top quality

One more noteworthy advantage is cost-effectiveness, particularly for tiny to medium-sized orders. Conventional display printing becomes economically viable just at greater quantities due to the configuration expenses involved. On the other hand, DTF printing removes these arrangement expenditures, making it extra inexpensive for smaller sets and one-off styles.

Furthermore, DTF printing stands out in durability and washability. Furthermore, DTF printing uses faster turn-around times.

Boosted Design Capabilities

DTF printing uses boosted design abilities that establish it apart from standard printing techniques. This innovation enables a broader range of vivid shades, detailed information, and nuanced slopes, providing developers with unprecedented versatility. The procedure involves printing a design onto a special film, which is then moved to textile. This permits high-resolution prints that keep quality and sharpness, even on facility patterns and tiny text.

Moreover, DTF printing sustains a large variety of fabrics, consisting of cotton, polyester, blends, and also non-textile substrates. This flexibility opens up doors for innovative applications in diverse industries such as style, home decoration, and marketing products. Unlike display printing, which can be limiting due to shade separation and pattern creation, DTF printing streamlines the process, making photo-realistic and multi-color styles more obtainable.

Furthermore, DTF printing masters accomplishing consistent color precision and vibrancy. This is essential for brand name consistency and conference customer assumptions. The technology likewise sustains unique impacts, such as metal finishes and glow-in-the-dark aspects, even more increasing creative opportunities. In significance, DTF printing encourages designers to press the borders of creative thinking, supplying visually stunning results that were previously unattainable.

Cost and Time Performance

One of the noteworthy advantages of DTF printing exists in its expense and time effectiveness, making it a preferred choice you could try here for many organizations. Unlike standard approaches that call for considerable financial investment in displays and configuration times, DTF printing allows for straight application onto different materials with marginal preparation.

Moreover, DTF printing masters creating brief runs and custom-made orders cost-effectively. The ability to generate high-quality prints without the demand for large quantity commitments lessens waste and optimizes source allotment. This adaptability is specifically beneficial for local business and startups that might not have the funding to spend in massive manufacturing runs.

In terms of functional efficiency, DTF printing's structured operations improves total efficiency. The modern technology's compatibility with a wide variety of substrates and textiles additionally broadens its application range, reducing the demand for several printing systems. Consequently, organizations can accomplish a faster turnaround time, enhancing customer fulfillment and competition out there. Hence, DTF printing attracts attention as a transformative service in the printing industry.

Future Trends in DTF Printing

Expecting future fads in DTF printing exposes a landscape noted by rapid technological developments and raised market demand (screen printing). One significant pattern is the assimilation of expert system (AI) and maker understanding algorithms to enhance print quality and enhance procedures. AI-driven systems can anticipate possible issues and readjust settings in real-time, guaranteeing regularly high-quality result

In addition, innovations in sustainable materials and green inks are anticipated to acquire traction. As environmental concerns come to be extra important, the market is likely to see a change towards non-toxic and biodegradable inks, reducing its eco-friendly footprint.

Customization and customization will also play a crucial function. With the growing customer demand for unique, customized products, DTF printing modern technologies are progressing to provide even more detailed and detailed customization alternatives. This pattern is sustained by improved software remedies that permit even more facility and creative layouts.

Finally, the integration of DTF printing with various other electronic platforms and click for info shopping services will certainly end up being more smooth. This connectivity will certainly make it possible for companies to offer on-demand printing solutions directly to customers, further driving development in the market. These fads jointly highlight a future where DTF printing not only satisfies but goes beyond the developing demands of the market.

Verdict

When contrasting DTF printing to conventional methods such as display printing and direct-to-garment (DTG) printing, a number of unique advantages emerge. Unlike screen printing, which typically needs specific fabric kinds, DTF printing can be applied to a wider range of products, including cotton, polyester, and blends, without endangering print high quality.

DTF printing supplies improved layout capabilities that establish it apart from traditional printing techniques. Hence, DTF printing stands out as a transformative service in the printing sector.

Advancements in DTF printing significantly boost the textile printing market by providing premium print convenience, quality, and effectiveness.

Report this page